✉️ [email protected] | 📞 +971-4-2675252

Home / Applications / Storage tank cleaning

Storage Tank Cleaning

The process of Storage tank cleaning is extremely important for any production/distribution system and unfortunately, it can be a hazardous and expensive task requiring much time and manpower.

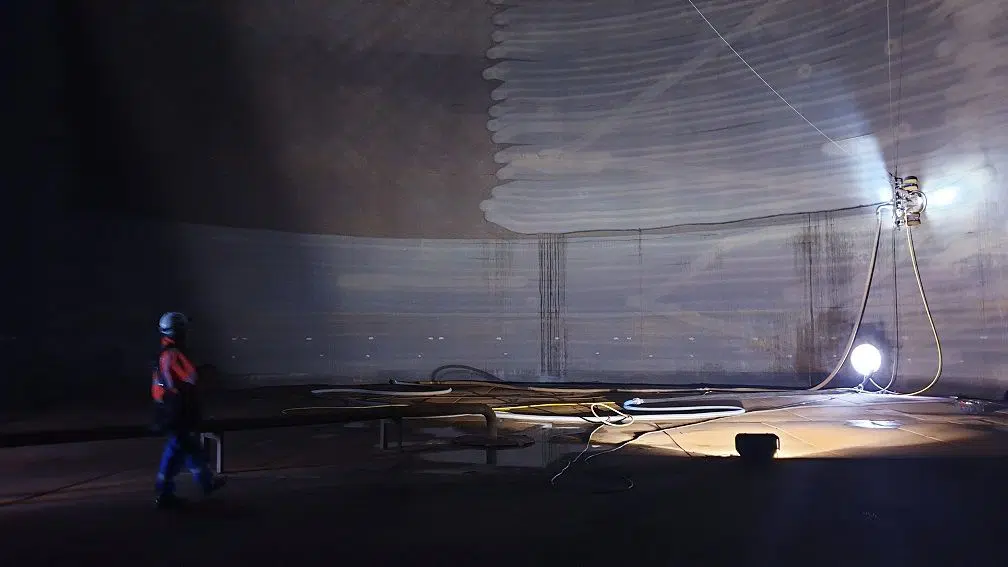

Storage tank cleaning

Why are Storage tanks Cleaned?

The regular cleaning of a storage tank is essential for maintaining health and safety standards and the absolute quality of the contents held within. Correctly conducted storage tank cleaning will help with:

Unwanted contamination: tank contamination in the form of microbes can cause line blockages, filter damage and product contamination, all of which are preventable through regular and efficient storage tank cleaning. Contamination can also occur on the external body of the tank in the form of rust which, if left untreated, can impact the structural integrity of the tank.

Overlooked internal or external damage: Internal/external tank deterioration, aging and mechanical problems (amongst other issues) can all be easily overlooked when a storage tank is cleaned irregularly. Cleaning assists with the efficiency of the inspection process of a storage tank, it can be as simple as removing a thick layer of dust to provide better insight into the tank’s condition.

Sludge: solids that are present are eventually broken down and settle on the bottom of the tank in the form of sludge. Sludge is a problem for storage tanks as it affects fluid movement within the tanks system when it blocks pipe systems and filters. Sludge can also significantly reduce the quality of the product within the tank through gradual contamination.

Paint Stripping: The protective paint which is located upon the external body of a storage tank must be reapplied regularly to prevent unwanted surface contamination. Removing the old paint with an efficient cleaning system is a crucial step to make before the reapplication a new coat. If paint stripping is conducted incorrectly, surface contamination and metal defects will almost certainly occur.

Storage tank cleaning

What are the methods used to clean Storage tanks?

Tank cleaning services can be conducted in a variety of ways to different degrees of efficiency. Generally, we see one of the following methods used in today’s storage tank cleaning market.

Manual Cleaning: Qualified confined space professionals are required to enter the storage tank to physically scrub its interior to complete the clean. For external cleaning, high pressure water blasting equipment is required with professionals who may be required to work at heights with certification.

Pros:

1) Cleaning is conducted in union with a visual inspection of the tanks condition.

Cons:

1) A lot of hands-on experience and safety related qualifications are required to complete the cleaning.

2) Cleaning is substantially more dangerous when people are working within the tank or at heights around the tank.

3) The duration of the clean is longer and the costs are often high.

Magnetic Robot Crawlers: A remotely controlled industrial tank cleaning robot enters the tank through the manhole or adheres to the wall on the outside and conducts the cleaning through the use of modern blasting and washing technology.

Pros:

1)Efficiency is high due to the combination of high performance and consistency.

2) Costs are low and the quality of the clean is high.

Cons:

1) None! The OPEX will drastically decrease

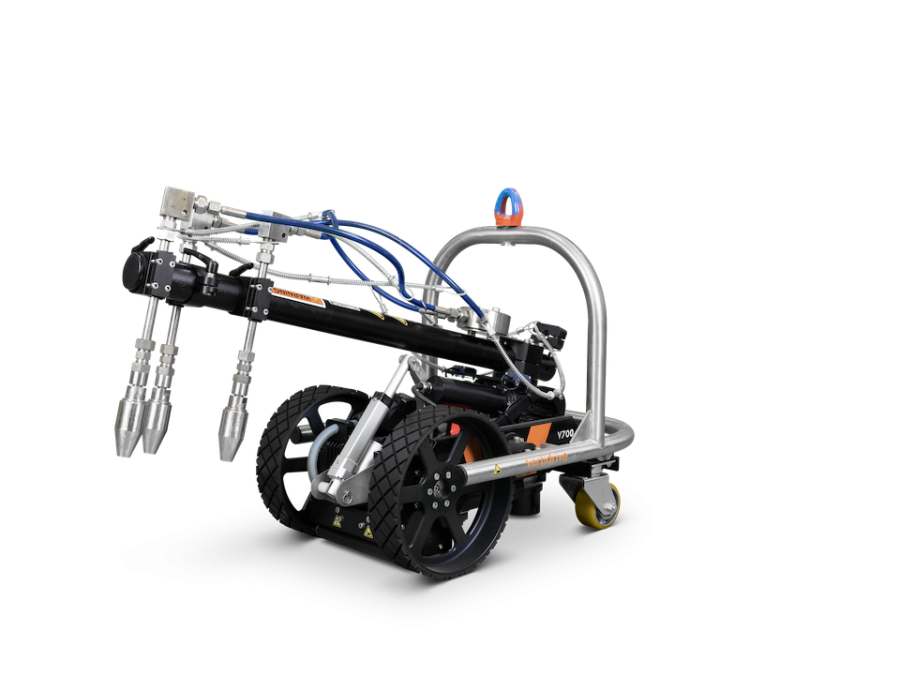

This tank cleaning robot system is a Vertidrive speciality for effective storage tank cleaning, paint stripping, and blasting.

Vertidrive

Vertidrive Storage tank cleaning solutions

The VertiDrive team are the proud designers/suppliers of the storage tank cleaning solutions: the VertiDrive M3, VertiDrive M4 and the Vertidrive M7.

The M3 and M7 are:

7x more efficient and, 8x faster than other storage tank cleaning methods, with up to 86% reduction in costs.

While the M4 is:

5x more efficient and faster than other methods, with up to 92% cost reduction. These VertiDrive solutions are specialized tank blasting robots that have been designed to clean storage tanks (amongst other metal surfaces) with maximum productivity and minimal operational costs. Each robot functions as a carrying platform for traditional hand-held blasting equipment, an operator simply needs to connect the robot to the hose line of a hand-held blaster, and they are ready to work. The selected solution will then convert the single hose-line of this hand-held system into 3 separate blasting nozzles which spread the blasting abrasive, with triple efficiency, across the desired surface. Important to note is that the operator will always be located safely on the ground, far away from any storage tank maintenance related hazards.

These tank cleaning robots can be used upon horizontal, overhead and vertical surfaces alongside curvatures and in corners through the use of permanent, powerful magnets.

Benefits

Benefits of Using Vertidrive

- Multi-purpose

- No need for scaffolding or cherry pickers

- Turns the work into a one-man job

- Safe, clean and efficient operations

- Closed systems available

- Low maintenance robots

- User friendly

Al Khamis products for Storage Cleaning

Vertidrive Solutions

Vertidrive V700

Our new robotic platform is designed specifically for tough industrial environments, ready for future demands. With powerful magnets, the V700 Series can work on any steel surface with magnetic properties, even upside down. Plus, it’s incredibly versatile.

Vertidrive V400

Our V400 Series introduces a break-through solution that surpasses the limitations of traditional UHP blasting methods. No longer accept slow production rates that average 5-8m² (53.8-86.1ft²) per hour, when you can experience an impressive average coverage of 45m² (484.4ft²) per hour.

Vertidrive M7

The VertiDrive M7 is a comprehensive solution for fast and efficient removal of industrial coatings, corrosion, and other types of contamination on large steel surfaces, such as storage tanks, ship hulls, and other large steel structures.