✉️ [email protected] | 📞 +971-4-2675252

Home / Applications / Abrasive Cutting

Abrasive Cutting

Al Khamis Equipment LLC, provides water pump solutions for Abrasive Cutting. Contact us to know more

Abrasive Cutting

What is Abrasive Cutting?

Abrasive water cutting, also known as waterjet cutting or abrasive jet cutting, is a machining process that utilizes a high-pressure stream of water mixed with abrasive particles to cut through various materials. It is a versatile and precise cutting method used in many industries.

The abrasive water cutting process involves the following steps:

- Pressurization: Water is pressurized to extremely high levels, typically between 30,000 and 90,000 pounds per square inch (psi), using a specialized water pump.

- Abrasive addition: Abrasive particles, such as garnet or aluminum oxide, are introduced into the high-pressure water stream. These particles act as cutting agents, enhancing the cutting effectiveness of the water jet.

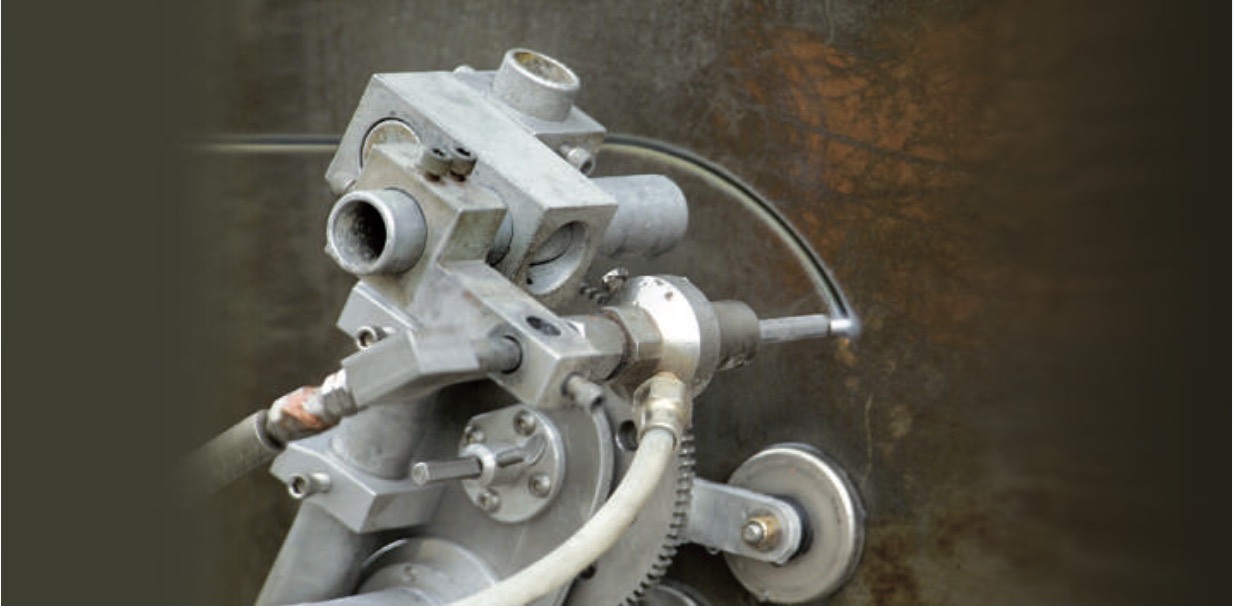

- Nozzle assembly: The high-pressure water and abrasive mixture is forced through a nozzle assembly, which is usually made of a hard material like tungsten carbide. The nozzle has a small orifice that helps create a focused and high-velocity stream of water.

- Cutting operation: The high-velocity water stream, carrying the abrasive particles, is directed towards the material to be cut. The abrasive particles in the water jet erode the material’s surface, while the high-pressure water helps flush away the cut material and debris.

The combination of the abrasive particles and the high-pressure water stream enables abrasive water cutting to effectively cut through a wide range of materials, including metals, plastics, glass, stone, ceramics, composites, and more. The process is known for its versatility and ability to handle materials with varying thicknesses and hardness levels.

One of the significant advantages of abrasive water cutting is its ability to produce precise cuts with minimal heat-affected zones. Since the cutting process is primarily mechanical, there is no heat generation during cutting, reducing the risk of material distortion or damage. It also eliminates the need for secondary finishing operations in many cases.

Additionally, abrasive water cutting is a relatively environmentally friendly process compared to some other cutting methods. It doesn’t involve the use of harmful chemicals or produce harmful fumes, and the water used in the process can often be recycled.

Overall, abrasive water cutting is a highly precise and versatile cutting method that can be used for various applications, ranging from industrial manufacturing and metal fabrication to artistic designs and architectural purposes.

Water Jetting machines

Water Jetting machines for Abrasive Cutting

Abrasive cutting is a term used when UHP water at 2500-3000bar is mixed with fine abrasive to form a powerful cutting jet able to cut through steel & concrete centimetres thick. The water jet travels at 500-600m/sec, carrying the abrasive which cuts the material.

Within the cutting nozzle assembly, the velocity of the water jet creates a venturi effect which draws in fine, dry abrasive which is metered from a nearby hopper. As there is virtually no heat or spark generation, this process is also referred to as Cold Cutting & is commonly used in hazardous areas such as in refineries or on offshore platforms. The abrasive nozzle attaches to a manipulator which is generally attached to the steel surface being cut with magnets. The nozzle is then moved with a hydraulic or pneumatic motor at a controlled speed depending on the thickness of the material being cut.

Benefits

Benefits of using Water Jetting machines

- Extreme accuracy of cut without any heat affected zone

- Leaves a machined like finish

- Edges can be bevelled for weld

- Will cut virtually any material

- Can be used in hazardous/ explosive areas

- Eliminates the need for plant shutdown

- Even suitable for decommissioning of munitions

- The process keeps the operator away from the cutting process

- Environmentally friendly, does not create any smoke or fumes

- The water jet is non-contact & therefore does not become blunt nor snags

- The pump is versatile & can be used for other cleaning & cutting applications

Al Khamis products for Abrasive Cutting

Pumps

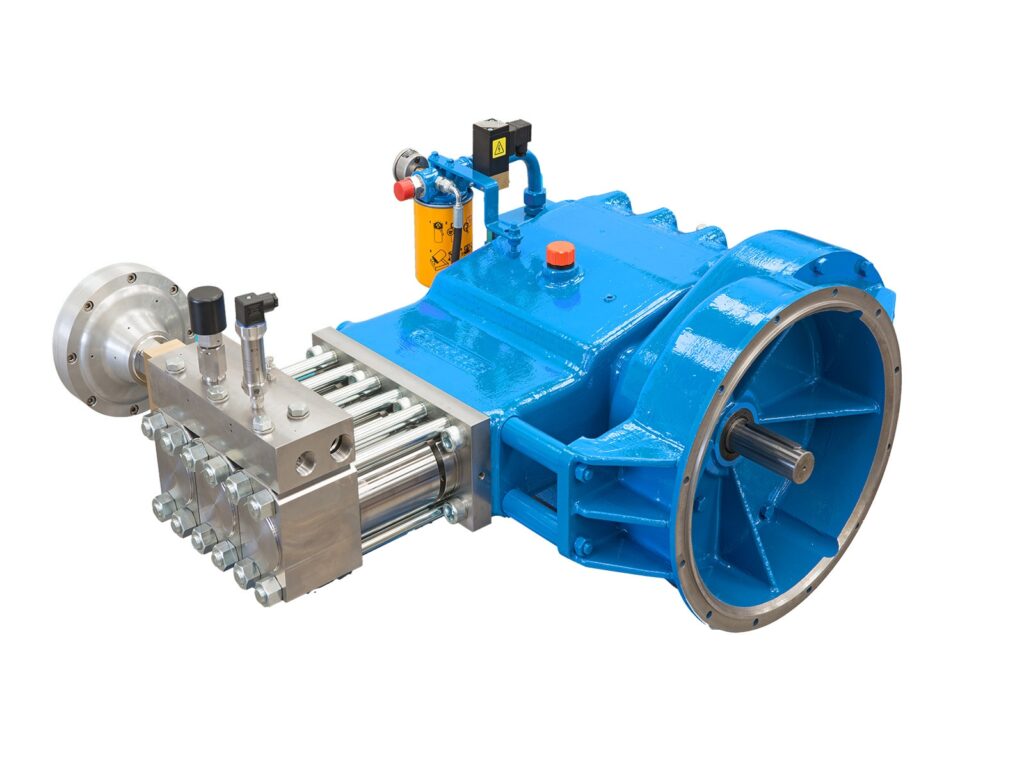

Hughes UB-30

Max Power:

220HP

160kw

Max Pressure:

2800 Bar

at 30 lpm

Max Flowrate:

44 lpm

at 2000 Bar

Hughes HP 220

Max Power:

220HP

160kw

Max Pressure:

1400 Bar

at 162 lpm

Max Flowrate:

277 lpm

at 310 Bar

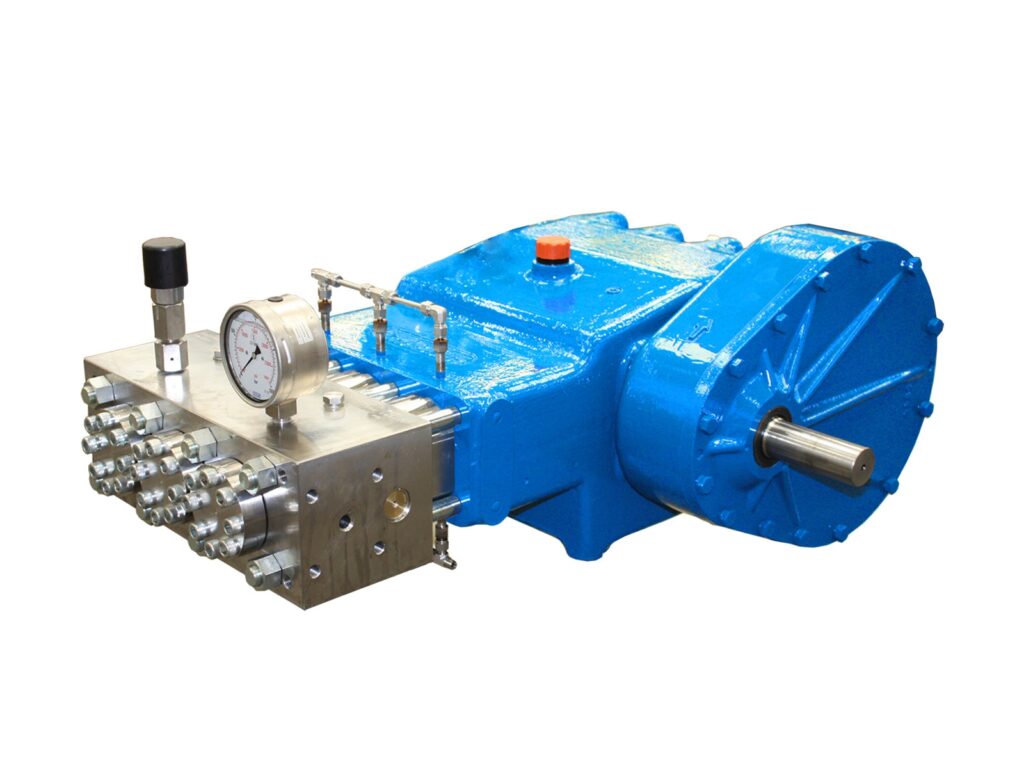

Hughes HP 120

Max Power:

120HP

90kw

Max Pressure:

1400 Bar

at 35 lpm

Max Flowrate:

277 lpm

at 175 Bar

Units

HP 220 Unit

- HP220 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.

HP 550 Unit

- HP550 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.