✉️ [email protected] | 📞 +971-4-2675252

Home / Applications / Heat Exchanger Cleaning

Heat Exchanger Cleaning

Heat exchangers need to be cleaned periodically to maintain their efficiency and performance. Al Khamis Equipment LLC provides water jetting solutions for heat exchanger cleaning

Heat Exchanger

What is a Heat Exchanger?

A heat exchanger is a device or system that allows for the transfer of heat between two or more fluids, which are typically at different temperatures. The purpose of a heat exchanger is to efficiently exchange heat energy from one fluid to another, without mixing them together.

Heat exchangers are widely used in various industries and applications, including HVAC (heating, ventilation, and air conditioning) systems, power generation plants, chemical processing plants, refrigeration systems, and automotive engines, among others.

The basic principle behind a heat exchanger is the transfer of heat through conduction. The hot fluid, known as the “hot side” or “primary fluid,” transfers its thermal energy to the cooler fluid, called the “cold side” or “secondary fluid,” through a solid barrier or a series of tubes or plates. The barrier or tubes allow the heat to pass from the hot side to the cold side while preventing the mixing of the fluids.

There are several types of heat exchangers, including:

- Shell and Tube Heat Exchanger: This is the most common type of heat exchanger. It consists of a shell (a large outer container) and tubes inside it. One fluid flows through the tubes, and the other fluid flows around the tubes in the shell.

- Plate Heat Exchanger: This type of heat exchanger consists of multiple thin plates stacked together with alternating hot and cold fluid channels. The large surface area of the plates facilitates efficient heat transfer.

- Finned Tube Heat Exchanger: These heat exchangers have tubes with extended surfaces or fins attached to them. Fins increase the heat transfer area and enhance heat exchange efficiency.

- Double-Pipe Heat Exchanger: It consists of two concentric pipes where one fluid flows through the inner pipe, and the other flows through the annular space between the inner and outer pipes.

- Air-to-Air Heat Exchanger (also known as heat recovery ventilator): It transfers heat between the outgoing and incoming air streams in HVAC systems, promoting energy efficiency.

The design and selection of a heat exchanger depend on factors such as the nature of the fluids, required heat transfer rates, space limitations, pressure and temperature constraints, and cost considerations.

Heat Exchanger Cleaning

Why should heat exchanger be cleaned?

Heat exchangers need to be cleaned periodically to maintain their efficiency and performance. Over time, various types of deposits and fouling can accumulate on the surfaces of the heat exchanger, which can negatively impact heat transfer and increase energy consumption. Here are some reasons why heat exchangers need to be cleaned.

- Scale and Mineral Deposits: When water or other fluids with high mineral content pass through the heat exchanger, scale deposits can form on the surfaces. Scale acts as an insulator, reducing heat transfer efficiency and increasing energy consumption. Regular cleaning helps remove scale deposits and restore heat exchanger performance.

- Corrosion: Corrosion can occur when the fluids flowing through the heat exchanger are chemically aggressive or when the heat exchanger materials are not compatible with the fluids. Corrosion can lead to the formation of rust and other corrosion products, which can hinder heat transfer. Cleaning helps remove corrosion products and prevent further damage.

- Biological Growth: In certain applications, such as cooling towers or HVAC systems, heat exchangers can be prone to biological growth, including algae, bacteria, and fungi. Biofilms and other organic deposits can reduce heat transfer efficiency and contribute to fouling. Regular cleaning helps eliminate these contaminants and maintain proper heat exchanger operation.

- Particulate and Solid Debris: In industrial processes or systems where fluids carry solid particles, such as sediment, dust, or debris, these particles can settle on the heat exchanger surfaces and impede heat transfer. Cleaning helps remove the particulate matter and prevent clogging or blockages.

- Efficiency and Performance: As deposits and fouling accumulate on the heat exchanger surfaces, the overall heat transfer efficiency decreases. This leads to increased energy consumption, reduced system performance, and higher operating costs. Regular cleaning helps restore the heat exchanger’s efficiency and maintain optimal performance.

By periodically cleaning heat exchangers, the risk of equipment failure, reduced heat transfer efficiency, increased energy consumption, and overall system inefficiency can be minimized. The cleaning methods and frequency depend on the specific type of fouling and the heat exchanger’s design, and it is essential to follow manufacturer guidelines and best practices for effective cleaning procedures.

Water Jetting machines

Water Jetting machines for Heat Exchanger Cleaning

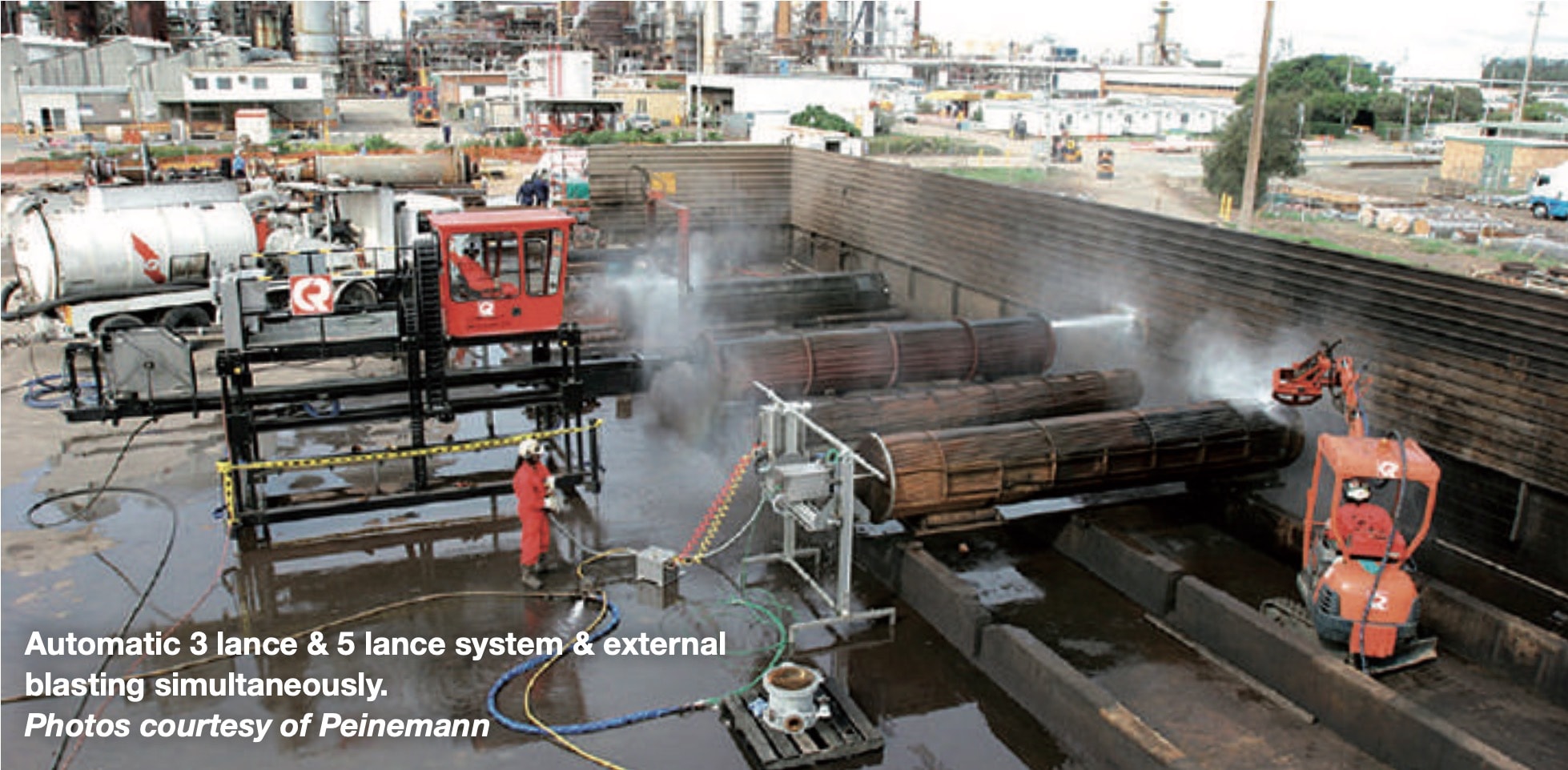

Heat exchangers used in industry are prone to scaling & blocking which drastically reduces heat transfer & efficiency of the process. High pressure water jetting is the fastest & most efficient method of cleaning internally & externally. At 1000bar the water jet removes scale & blockages with ease, leaving a polished finished on the inside wall of the tube thus slowing down future scale build up.

Each lance will pass 30-40lpm at 1000bar. The smaller pumps are generally used with a single lance & foot operated control valve to control pressure on/off. The lance could be hand held but Hughes Pumps recommend a 1-LTC which takes the lance out of the operators hands for increased safety. As pump size/ flow increase as can the quantity of lances, up to the 5 lance bundle blaster for maximum productivity, automation & safety.

Benefits

Benefits of using Water Jetting machines

- Environmentally friendly.

- Faster than any other cleaning.

- More thorough than any other cleaning method.

- No mechanical damage to the tubes.

- Leaves a polished finish.

- Only uses water, no chemicals to dispose of.

- Heat exchangers can be cleaned in-situ or taken to a cleaning bay for shutdown maintenance.

- Fully automated systems available for maximum safety & productivity.

- Flexible lances can negotiate a U bend.

- The pump is versatile & can be used for other cleaning applications in the plant e.g. pipe cleaning, tank cleaning etc.

Al Khamis products for Heat Exchanger Cleaning

Pumps

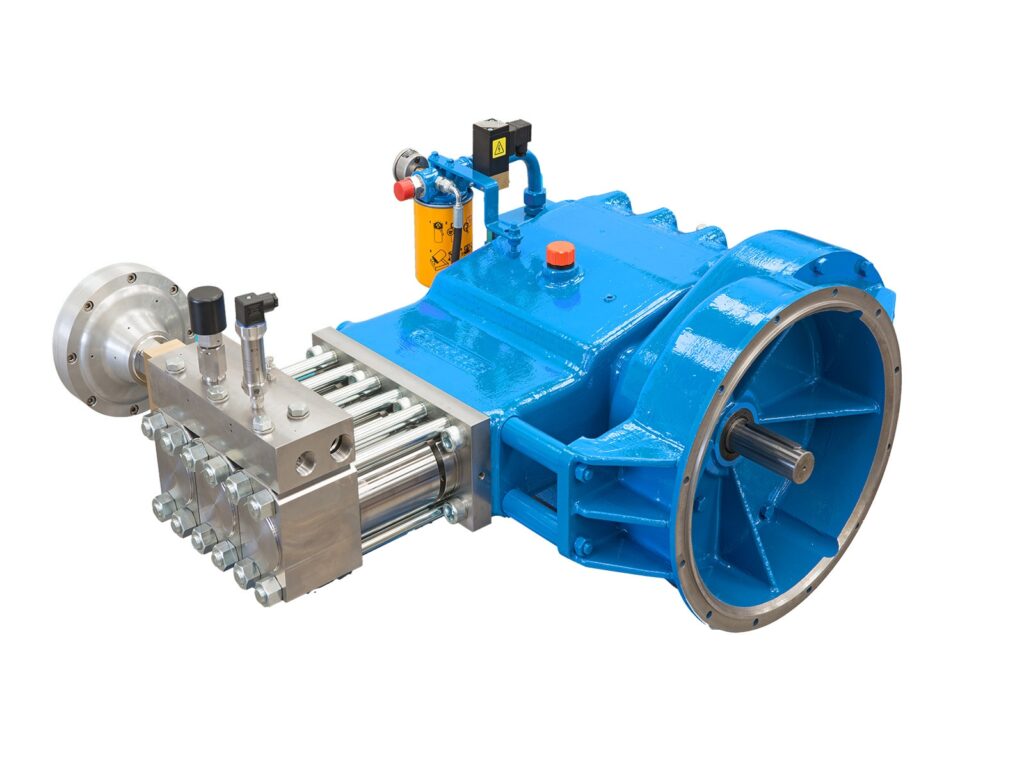

Hughes UB-30

Max Power:

220HP

160kw

Max Pressure:

2800 Bar

at 30 lpm

Max Flowrate:

44 lpm

at 2000 Bar

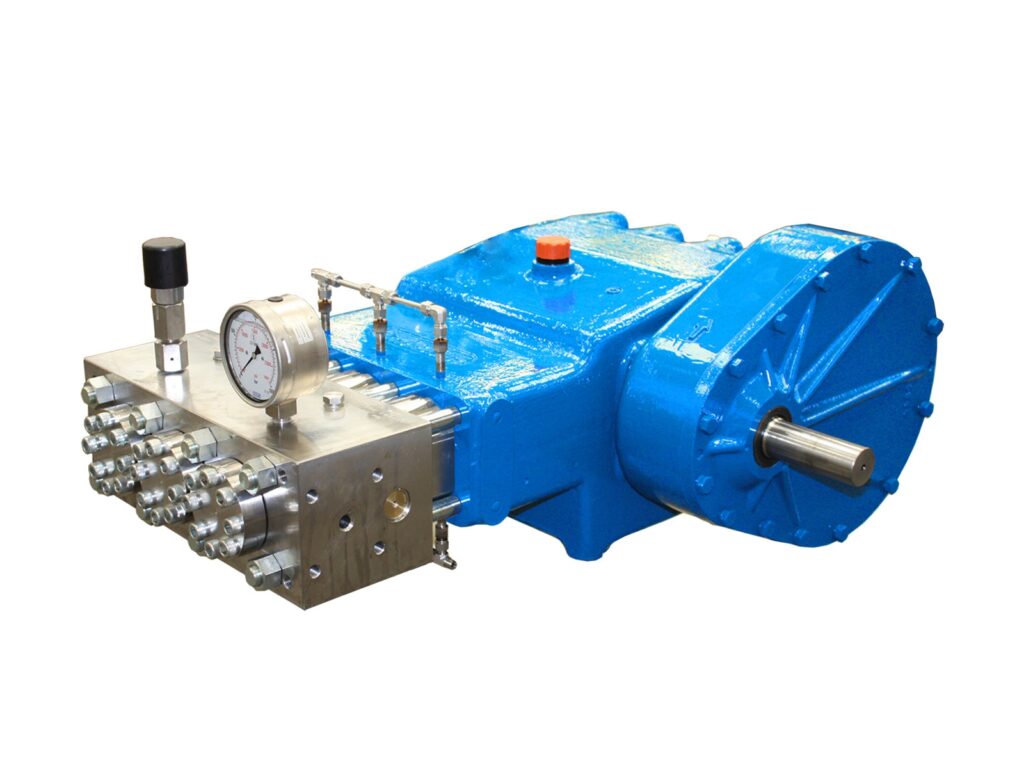

Hughes HP 220

Max Power:

220HP

160kw

Max Pressure:

1400 Bar

at 162 lpm

Max Flowrate:

277 lpm

at 310 Bar

Hughes HP 120

Max Power:

120HP

90kw

Max Pressure:

1400 Bar

at 35 lpm

Max Flowrate:

277 lpm

at 175 Bar

Units

HP 220 Unit

- HP220 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.

HP 550 Unit

- HP550 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.