✉️ [email protected] | 📞 +971-4-2675252

Home / Applications / Hydrodemolition

Hydrodemolition

Pipes are essential to a wide range of industries and maintaining pipes. Al Khamis LLC UAE provides pump units and accessories designed for pump cleaning.

Hydrodemolition

What is Hydrodemolition?

Hydrodemolition is a technique used for the removal of deteriorated or damaged concrete structures. It involves using high-pressure water jets to break up and remove concrete from surfaces such as walls, floors, or bridges. The process is also known as hydroblasting, hydro milling, or water jetting.

In hydrodemolition, a specialized machine or robot directs a focused jet of water at high pressure onto the concrete surface. The water pressure, typically ranging from 14,500 to 20,000 pounds per square inch (psi), is capable of breaking down the concrete matrix without damaging the underlying rebar or structure. The water jet can be controlled to remove concrete to a specific depth, allowing for precise and controlled demolition.

The advantages of hydrodemolition include:

- Precision and control: The water jet can be directed precisely to remove only the deteriorated or damaged concrete, leaving the surrounding areas intact.

- Non-destructive to rebar: The high-pressure water jet selectively removes concrete without damaging the reinforcing steel bars (rebar) embedded within the structure.

Reduced vibration and noise: Unlike traditional methods such as jackhammers or breakers, hydrodemolition generates minimal vibration and noise, making it suitable for sensitive environments or urban areas. - Safer for operators: Hydrodemolition eliminates the risks associated with hand-arm vibration syndrome (HAVS) that operators can experience from using pneumatic tools.

- Improved surface preparation: Hydrodemolition creates a roughened profile on the concrete surface, enhancing bonding for repairs or overlays.

Hydrodemolition is commonly used in various applications, including the repair and maintenance of bridges, dams, parking structures, industrial floors, and other concrete surfaces. It allows for efficient and controlled removal of deteriorated concrete, providing a clean and sound substrate for subsequent repairs or rehabilitation.

Water Jetting machines

Water Jetting machines for Hydrodemolition

Hydrodemolition (also referred to as concrete cutting) is a process of using a water jet at 1000 to 1400bar (14,500 to 20,000psi) to remove loose, deteriorated & damaged concrete from road bridges & other concrete structures & to expose steel reinforcing bars for inspection.

Many jobs are carried out using a hand held jetting gun. In these circumstances the reaction force created by the water jet should not exceed 250 Newton’s (25kgf) to ensure the operator can work in a safe manner e.g. 35lpm at 1400bar.

Higher flowrate increases reaction force so the cutting nozzle needs to be constrained. At 120lpm at 1000bar it is common to use a gimbal device to connect the jetting gun to. For maximum productivity the HP500 pump with a performance of 200lpm at 1000bar is coupled to a hydrodemolition robot.

Benefits

Benefits of using Water Jetting machines

- Leaves a sound surface ready for repair

- Good quality concrete is unaffected

- No micro cracks which pneumatic hammers cause

- Vibration to the surrounding structure eliminated

- Faster than any other process

- Steel reinforcing bars do not get damaged but are blasted by the water jet & concrete particles to descale them

- Depth of cut is controllable

- Robots keep the operator away from the waterjet

- Robots are programmable to provide accurate, consistent results

- Can be used to clean & roughen (scabble) concrete surfaces.

- The pump is versatile & can be used for other cleaning & cutting applications

Al Khamis products for Pipe Cleaning

Pumps & Accessories

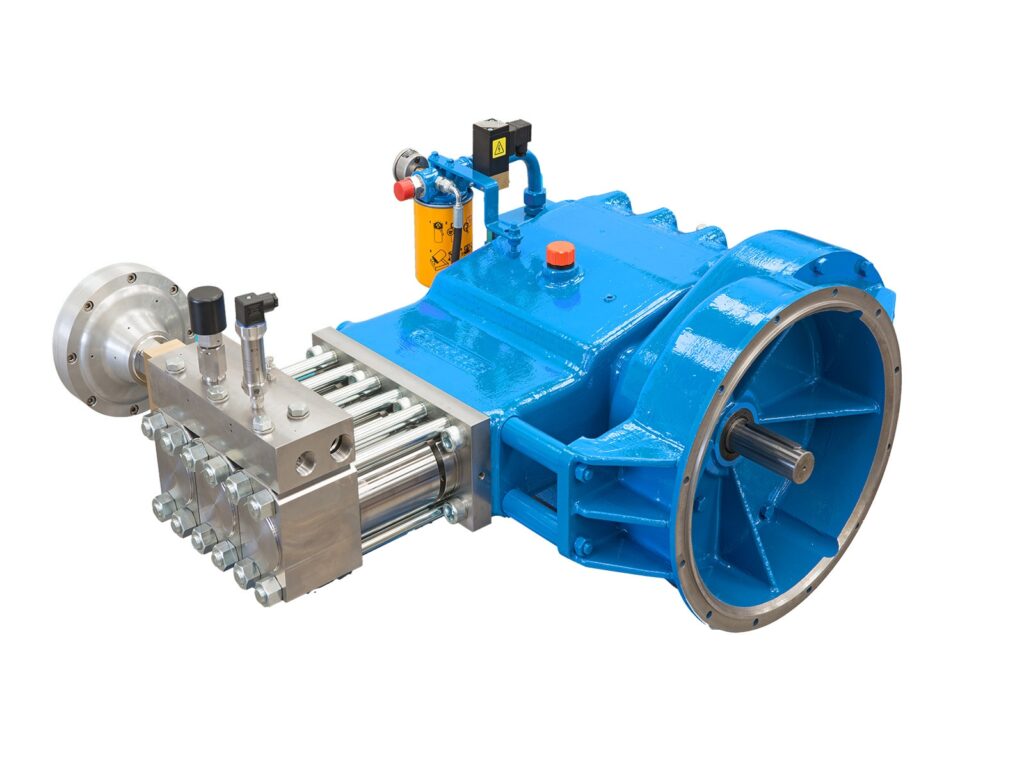

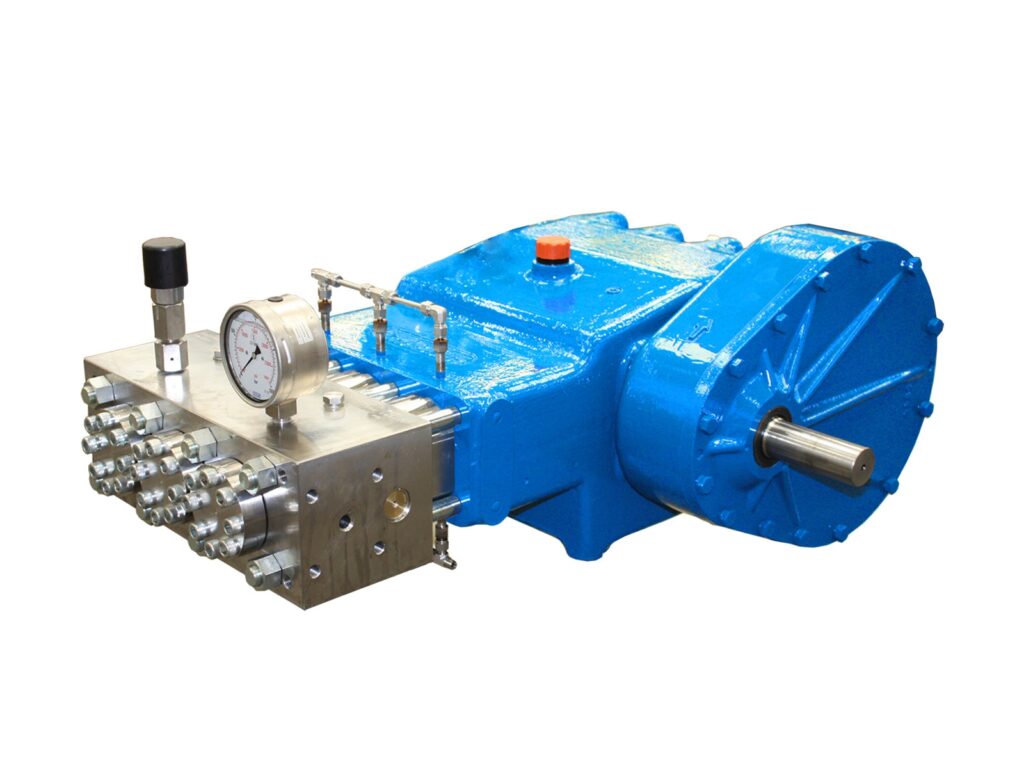

Hughes UB-30

Max Power:

220HP

160kw

Max Pressure:

2800 Bar

at 30 lpm

Max Flowrate:

44 lpm

at 2000 Bar

Hughes HP 220

Max Power:

220HP

160kw

Max Pressure:

1400 Bar

at 162 lpm

Max Flowrate:

277 lpm

at 310 Bar

Hughes HP 120

Max Power:

120HP

90kw

Max Pressure:

1400 Bar

at 35 lpm

Max Flowrate:

277 lpm

at 175 Bar

Units

HP 220 Unit

- HP220 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.

HP 550 Unit

- HP550 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.