✉️ [email protected] | 📞 +971-4-2675252

Home / Applications / Pipe Cleaning

Pipe Cleaning

Pipes are essential to a wide range of industries and maintaining pipes. Al Khamis LLC UAE provides pump units and accessories designed for pump cleaning.

Pipe Cleaning

Why do pipes need to be cleaned?

- Accumulation of debris and sediment: Over time, pipes can accumulate various substances like dirt, minerals, grease, hair, soap scum, and other debris. This buildup can restrict the flow of water, leading to clogs and reduced water pressure. Regular cleaning helps remove these deposits and keeps the pipes clear.

- Prevention of clogs: As debris accumulates in pipes, it can form clogs that block the flow of water or sewage. Clogs can cause drains to back up, toilets to overflow, or sinks and tubs to drain slowly. Regular cleaning helps prevent these clogs from occurring, reducing the chances of plumbing emergencies.

- Elimination of odors: Organic matter and bacteria that accumulate in pipes can produce unpleasant odors. Cleaning the pipes removes these odor-causing substances, resulting in fresher-smelling drains and a more pleasant environment

- Prevention of corrosion: Some pipes, particularly metal pipes, are susceptible to corrosion due to the presence of chemicals or minerals in the water. Corrosion can weaken the pipes, leading to leaks and potential water damage. Regular cleaning can help remove corrosive substances and extend the lifespan of the pipes.

- Maintenance of water quality: In some cases, pipes can accumulate bacteria, fungi, or other microorganisms that may affect the quality of the water. Regular cleaning can help maintain clean and hygienic pipes, ensuring the delivery of safe and potable water to your taps.

Overall, regular cleaning of pipes helps maintain their efficiency, prevents clogs and damage, eliminates odors, and ensures the delivery of clean water. It is a crucial part of plumbing maintenance to keep your plumbing system in good working order.

Pipe Inspection

Pipe Inspection

The first step is to inspect the pipeline to determine the extent of buildup or damage. This can be done using various inspection techniques such as video cameras, ultrasonic testing, or magnetic flux leakage.

Contact us to learn more about pipe inspection cameras

Water Jetting machines

Water Jetting machines for Pipe Cleaning

When cleaning drains and pipes, hydro jetting, also known as water jetting or high-pressure pipe cleaning, is a safe and efficient alternative to using chemicals or upsetting plumbing systems. Through the use of high-pressure water, hydro jetting can remove clogs and debris from your pipes and drains without the need for digging in the ground or other invasive techniques. This makes water jetting more affordable and environmentally friendly because it doesn’t involve digging or the use of dangerous or abrasive chemicals.

Process pipe work in industry becomes corroded, scaled up or even totally blocked which reduces plant efficiency, even stopping production. A range of pressures between 500 & 3000bar can be used to clean pipes, depending on the type of deposit but 1000bar is a useful performance for a variety of cleaning tasks.

Fixed or rotating nozzles with partially rearward facing jets create thrust which pulls the hose into the pipe. The spent water then flushes the

debris to the open ended pipe. As pipe diameter increases, more flow is required to provide adequate flushing & nozzle centralisers are used with extension arms to keep the nozzle close to the pipe wall for maximum impact. The Rotocar Cleaning system allows very long pipe runs with multiple bends to be cleaned from one end. A special unbalanced nozzle hugs the pipe wall while the hose is rotated & fed into the pipe.

Benefits

Benefits of using Water Jetting machines

- Pipe diameters from 10 to 1000mm plus can be cleaned

- Any deposit can be removed e.g. scale, corrosion, process deposits & even concrete

- Vertical pipes can be cleaned from top or bottom.

- The jetting process flushes debris back to the open ended pipe as the hose is withdrawn.

- Totally blocked pipes can be cleared.

- The Rotocar system allows virtually any diameter & length of pipe to be cleaned, irrespective of bends.

- Steel pipe can be cleaned to white metal if 2000-3000bar is used.

- Water jets will not damage or roughen the pipe surface.

- The pump is versatile & can be used for other cleaning/cutting or pressure testing applications.

Al Khamis products for Pipe Cleaning

Pumps & Accessories

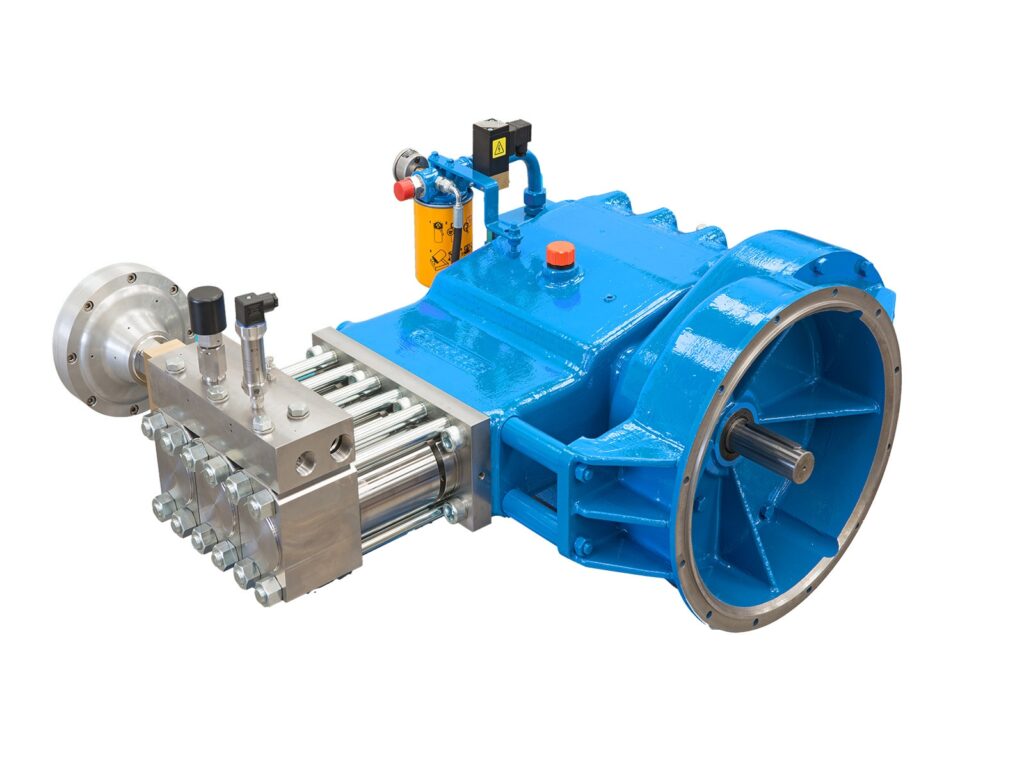

Hughes UB-30

Max Power:

220HP

160kw

Max Pressure:

2800 Bar

at 30 lpm

Max Flowrate:

44 lpm

at 2000 Bar

Hughes HP 220

Max Power:

220HP

160kw

Max Pressure:

1400 Bar

at 162 lpm

Max Flowrate:

277 lpm

at 310 Bar

SMC Bomb Nozzle

SMC Bomb Nozzles are the best choice to clean up sewerage networks that are almost blocked with various sizes of stones due to their heavy weight and great power. The nozzles are made of hardened stainless steel, with a single forward jet pattern, as well as backward outlet jet patterns at two different angles (10° & 30°).

Units

HP 220 Unit

- HP220 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.

HP 550 Unit

- HP550 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.