✉️ [email protected] | 📞 +971-4-2675252

Home / Applications / Ship Hull Cleaning & Blasting

Ship Hull Cleaning & Blasting

Al Khamis has a number of products suited for shipyard work. Including high pressure water jetting machines and magnetic crawlers.

Shipyard

Why are Ship Hulls Cleaned?

Hull cleaning and blasting assists with the removal of unwanted roughness and marine fouling from a ship’s belly (the buildup of organisms who have attached themselves to the hull such as mussels, barnacles and tubeworms). When marine growth is allowed to develop on the hull and propeller, the subjective vessel will experience an increase in drag. This increased drag negatively impacts the relationship between fuel consumption, speed and power and therefore, the overall efficiency of the ship.

Ships hull cleaning is important because:

- Cleaning the hull reduces a ships fuel consumption,

- Manufactured vessel speed is maintained through the reduction of drag,

- Any hull related issues/damage can easily be viewed and repaired,

- Future anti foul removal costs are minimized,

- Engine overheating is prevented (blocked intakes),

- Biofouling and the presence of invasive species is reduced (for many countries this is becoming increasingly important).

Shipyard

What are the methods used to clean Ship Hulls?

Today, many methods are used for ship hull cleaning and maintenance. However, years ago ship hull maintenance was completed by hand through the utilization of scrappers and chippers. One can imagine that the job was a dauntingly laboursome task that required a lot of manpower and time. Ship hull cleaning by hand is still used today in certain situations however, it is often forgotten when more practical, safer, and time-effective methods are available. Some of these methods include UHP equipment such as high pressure water blasting, underwater brush karts systems magnetic robot crawlers.

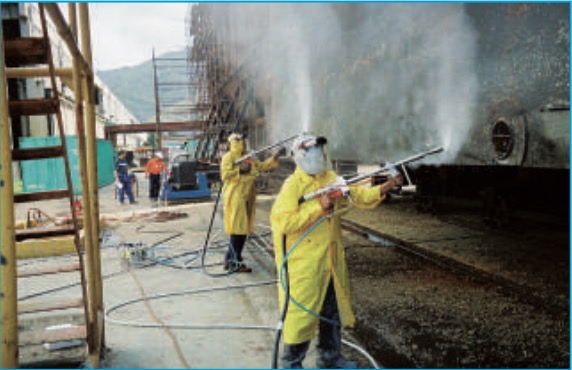

High Pressure Water Blasting: High pressure water blasting systems are routinely used for ship hull maintenance. This method functions as a manual hull cleaning method with an operator who is required to direct and manage the water blaster.

Underwater Brush Karts: A method of underwater hull cleaning. Hydraulics propel industrial brushes below the body of the brush kart. These various brushes work collectively to scrub away any marine growth on the ship’s hull and propeller. What is undesirable about this process is that the body of the kart itself is fairly large (up to 170 kg in weight) and requires a highly trained diver to direct and operate the system.

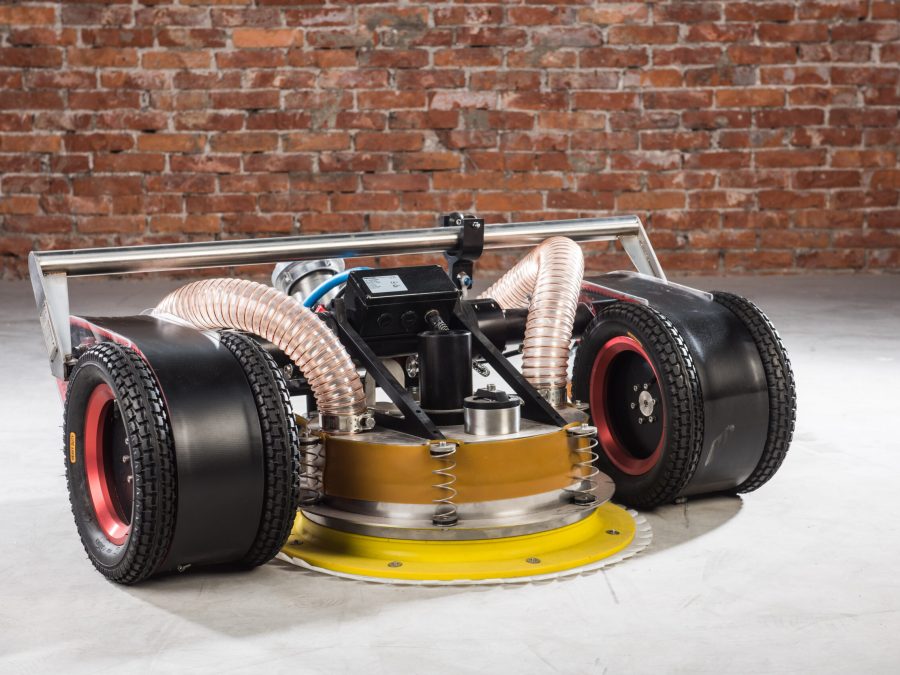

Magnetic Robot Crawlers: A magnetic robot crawler is a dry-dock cleaning robot that completes antifoul removal via remote control. Powerful, permanent attached magnetics allow the robot to operate across the entirety of a ship’s hull while the operator is at a safe distance. The operator needs to connect a manual blasting system to the robot, place the robot securely on the hull of the ship and the crawler is ready to go. The magnetic crawler is a Vertidrive specialty for effective ship hull cleaning and maintenance.

Vertidrive

Vertidrive Abrasive Blasting solutions

The VertiDrive team are the proud designers/suppliers of the abrasive and water blasting robot solutions: the VertiDrive M3, VertiDrive M4 and the Vertidrive M7.

The M3 and M7 are: 7x more efficient and, 8x faster than manual ship hull cleaning methods, with up to 86% reduction in costs.

While the M4 is: 5x more efficient and faster than manual methods, with up to 92% cost reduction.

All of the previously mentioned VertiDrive solutions are hull blasting robots that have been designed to clean vessels with maximum productivity and minimal operational costs. Each functions as a carrying platform for traditional hand-held blasting equipment, an operator simply needs to connect the robot to the hose line of a hand-held blaster and they are ready to work. Important to note is that the operator will always be located safely on the ground, far away from any ship hull maintenance related hazards.

These ship hull cleaning robots can be used for ship anti foul removal within a dry dock cleaning scenario. Horizontal, vertical, curvatures, corners and overhead surfaces are all a breeze for these robots through the use of permanent, powerful magnets.

Benefits

Benefits of Using Vertidrive

- Multi-purpose

- No need for scaffolding or cherry pickers

- Turns the work into a one-man job

- Safe, clean and efficient operations

- Closed systems available

- Low maintenance robots

- User friendly

Vertidrive Solutions

Vertidrive M3

- 60 m2 / 646 ft2 per hour

- 8x faster than manual work

- Horizontal, overhead and vertical surfaces

- Multi-purpose solution

- Interchangeable applications

- 1500 mm(60″) cleaning width

- Remote Controlled

- Controlled to Vertidrive M4

- Versions: Electric, Pneumatic, ATEX Zone II

- Fits through 24″ manhole

Vertidrive M4

- 45m2 / 485 ft2 per hour

- 5x faster than manual work

- Horizontal and vertical surfaces

- Closed hydroblasting and vertical surfaces

- 400mm(15.5″) cleaning width

- Remote Controlled

- Easy to (dis)assemble

- Convertible to Vertidrive M3

- Versions: Electric, Pneumatic, ATEX Zone II

- Fits through 24″ manhole

Vertidrive M7

- 60 m2 / 646 ft2 per hour

- 8x faster than manual work

- Horizontal, overhead and vertical surfaces

- Multi-purpose solution

- Interchangeable applications

- Multi-directional swing arm

- 1500mm(60″) cleaning width

- Compact, agile design for smaller working radius

- Wireless control

- Powered by 70Vdc motors

Water Jetting Machines

Water Jetting Machines for Ship yard Applications

Water jetting is widely used in the ship repair & marine industries.

300bar is used to remove marine growth & salt deposits prior to grit blasting. Larger pumps can be specified to allow multiple jetting guns to be used simultaneously.

700-1000bar will remove loose coatings & corrosion, leaving sound coatings intact, ready for repainting if total coating removal is not required. It is often said that if 1000bar does not remove the coating then it is sound enough to paint over.

2750bar (UHP) will remove all coatings & corrosion back to white metal. Marine paint manufacturers have developed paints to apply to hydro-blasted surfaces & actively promote this method as it removes all chlorides & provides the best possible surface for recoating.

Benefits

Benefits of Water Jetting

- Dust free allowing other trades to work in the vicinity

- Minimal waste disposal, 98% less than grit blasting Ultrabar 24DC with twin gun operation, 2750bar

- Environmentally friendly

- No contamination of sensitive rotating equipment

- Removes all chlorides from substrate leaving a perfect surface for new paint

- Unlike grit blasting does not profile steel so does not trap chloride contaminants in the substrate

- Minimal water consumption, most of which evaporates when using UHP

- Reduces time during dry-docking

- Sheeting not required

- Can be used in wet & windy conditions

- The pump is versatile & can be used for other cleaning & cutting applications

Al Khamis products for Shipyard

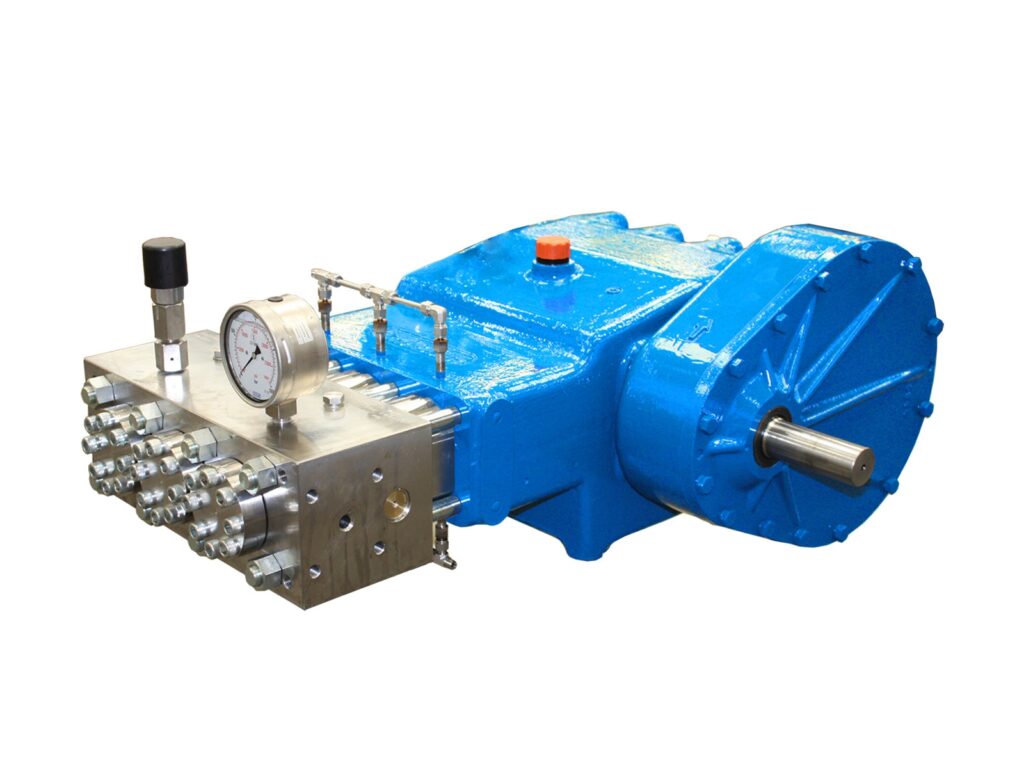

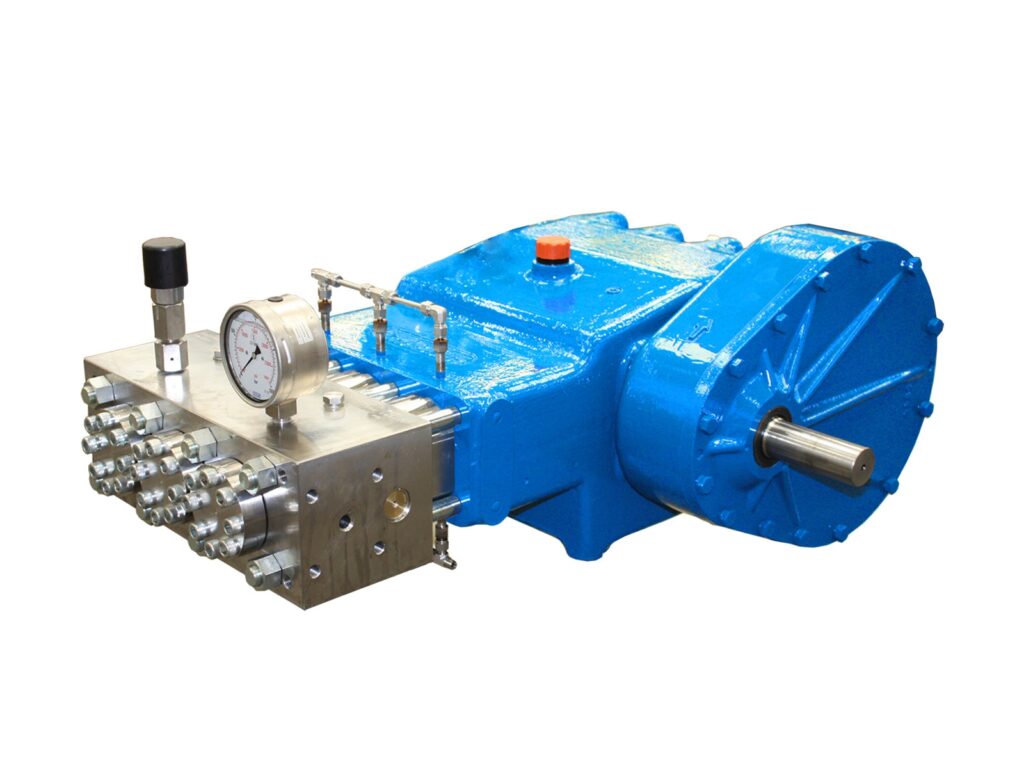

Pumps & Accessories

Hughes HP 220

Max Power:

220HP

160kw

Max Pressure:

1400 Bar

at 162 lpm

Max Flowrate:

277 lpm

at 310 Bar

Hughes HP 120

Max Power:

120HP

90kw

Max Pressure:

1400 Bar

at 35 lpm

Max Flowrate:

277 lpm

at 175 Bar

Hughes HP 120

Max Power:

120HP

90kw

Max Pressure:

1400 Bar

at 35 lpm

Max Flowrate:

277 lpm

at 175 Bar

Units

HP 220 Unit

- HP220 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.

HP 550 Unit

- HP550 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.

Vertidrive M3

- 60 m2 / 646 ft2 per hour

- 8x faster than manual work

- Horizontal, overhead and vertical surfaces

- Multi-purpose solution

- Interchangeable applications

- 1500 mm cleaning width

- Remote Controlled