✉️ [email protected] | 📞 +971-4-2675252

Home / Applications / Subsea Cleaning

Subsea Cleaning

Subsea Cleaning machines allows us to clear out marine growth in a variety of surfaces including ship hulls and man-made lake bed.

Subsea Cleaning

What is Subsea Cleaning?

Subsea cleaning refers to the process of cleaning underwater structures and equipment. It is necessary in industries such as offshore oil and gas, marine transportation, and underwater infrastructure maintenance. Subsea cleaning helps remove marine growth, sediments, corrosion, and other contaminants that can negatively impact the performance and integrity of underwater assets.

Applications

Applications for Subsea Cleaning

Offshore oil and gas industry:

Subsea cleaning is vital in the oil and gas sector for maintaining underwater equipment, pipelines, and platforms. It helps remove marine growth, sediments, and corrosion to ensure the efficient operation of production systems and the integrity of subsea infrastructure.

Marine transportation and shipping:

Water jetting is used for cleaning ship hulls, propellers, and other submerged parts to reduce drag, increase fuel efficiency, and prevent the spread of invasive species.

Underwater infrastructure maintenance:

Subsea cleaning is required for the maintenance of underwater infrastructure, including bridges, tunnels, ports, and piers. It helps remove marine growth and sediment buildup, ensuring structural integrity and preventing damage.

Water Jetting Machines

Water Jetting Machines for Subsea Cleaning

Water jetting is widely used in the ship repair & marine industries. 300bar is used to remove marine growth & salt deposits prior to grit blasting. Larger pumps can be specified to allow multiple jetting guns to be used simultaneously. 700-1000bar will remove loose coatings & corrosion, leaving sound coatings intact, ready for repainting if total coating removal is not required. It is often said that if 1000bar does not remove the coating then it is sound enough to paint over. 2750bar (UHP) will remove all coatings & corrosion back to white metal. Marine paint manufacturers have developed paints to apply to hydro-blasted surfaces & actively promote this method as it removes all chlorides & provides the best possible surface for recoating.

Benefits

Benefits of Water Jetting

Dust free allowing other trades to work in the vicinity.

- Minimal waste disposal, 98% less than grit blasting.

- Environmentally friendly.

- No containment of sensitive rotating equipment.

- Removes all chlorides from substrate leaving a perfect surface for new paint.

- Unlike grit blasting does not profile steel so does not trap chloride contaminants in the substrate.

- Minimal water consumption, most of which evaporates when using UHP.

- Reduces time during dry-docking.

- Sheeting not required.

- Can be used in wet & windy conditions.

- The pump is versatile & can be used for other cleaning & cutting applications.

Al Khamis products for Subsea Cleaning

Pumps & Accessories

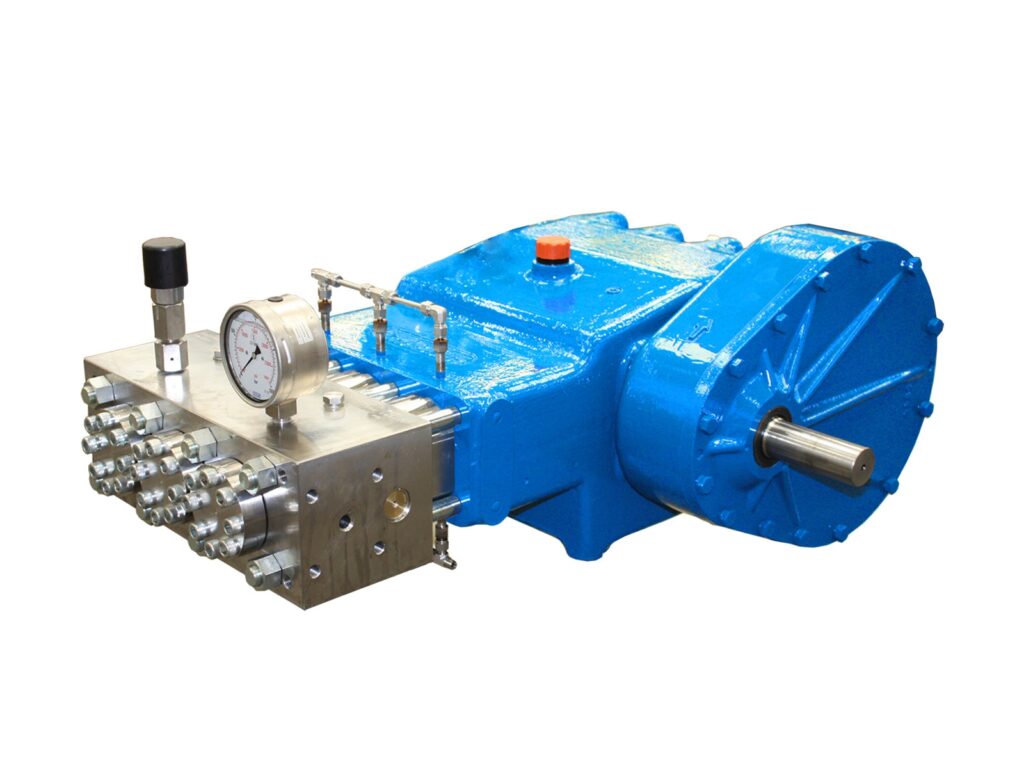

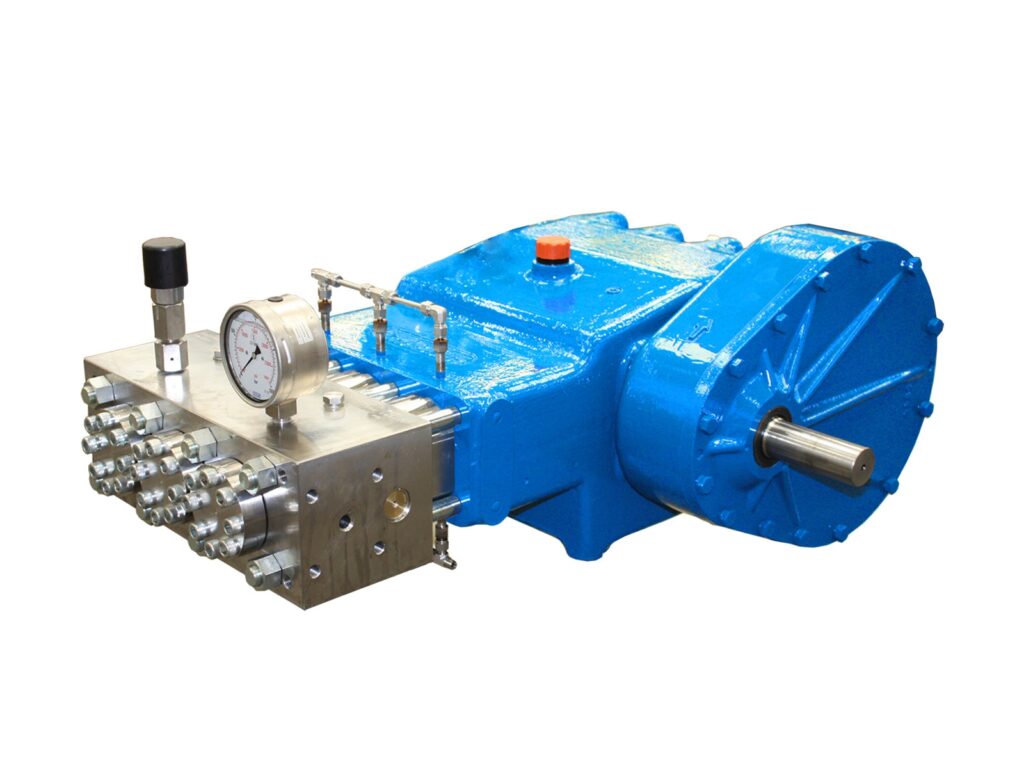

Hughes HP 220

Max Power:

220HP

160kw

Max Pressure:

1400 Bar

at 162 lpm

Max Flowrate:

277 lpm

at 310 Bar

Hughes HP 120

Max Power:

120HP

90kw

Max Pressure:

1400 Bar

at 35 lpm

Max Flowrate:

277 lpm

at 175 Bar

Hughes HP 120

Max Power:

120HP

90kw

Max Pressure:

1400 Bar

at 35 lpm

Max Flowrate:

277 lpm

at 175 Bar

Units

HP 220 Unit

- HP220 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.

HP 550 Unit

- HP550 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.

Vertidrive M3

- 60 m2 / 646 ft2 per hour

- 8x faster than manual work

- Horizontal, overhead and vertical surfaces

- Multi-purpose solution

- Interchangeable applications

- 1500 mm cleaning width

- Remote Controlled