✉️ [email protected] | 📞 +971-4-2675252

Home / Applications / Surface Preparation

Surface Preparation

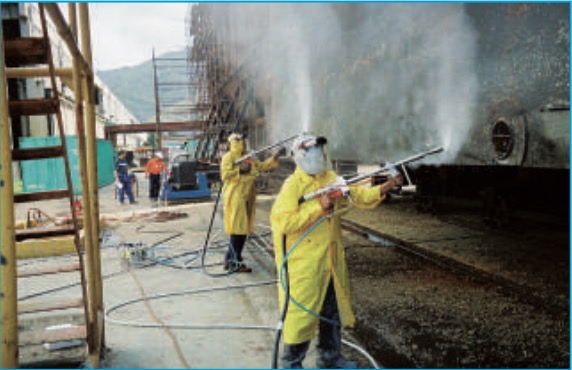

Surface Preparation requires Ultra High Pressure Water Jetting/HydroBlasting machines. At Al Khamis you can find UHP units that are custom built for your needs.

Surface Preparation

What is Surface Preparation?

Surface Preparation refers to the treatment of the surface of a material prior to coating application, the use of adhesives, maintenance, repair, welding, painting, water-proofing, corrosion-proofing.

Surface preparation ensures that a material is ready to receive a coating. A dirty, oily, flaking or otherwise compromised surface can greatly reduce the effectiveness of a new coating, cause adhesion failure or otherwise undermine a process.

Applications

Applications of Surface Preparation

Automotive industry:

Preparing the surface is essential in the automotive industry for tasks such as painting, powder coating, and adhesive bonding. It ensures proper adhesion and durability of the applied coatings or adhesives.

Construction and infrastructure:

Preparing the surface plays a vital role in construction and infrastructure projects. It is necessary for applying coatings, sealants, or adhesives to surfaces like concrete, steel, or wood. Proper surface preparation helps enhance the longevity and performance of structures.

Manufacturing and fabrication:

Surface preparation is often required in manufacturing and fabrication processes. It ensures that surfaces are clean and free from contaminants, allowing for better welding, soldering, or joining of parts.

Marine industry:

In the marine industry, surface preparation is crucial for ship maintenance and repair. It involves removing marine growth, rust, old coatings, and other contaminants from the ship’s hull and other surfaces to prevent corrosion and maintain performance.

Oil and gas industry:

Surface preparation is critical in the oil and gas industry for various applications. It involves preparing surfaces of pipelines, storage tanks, and equipment for coating applications to protect against corrosion and maintain operational efficiency.

General maintenance and repair:

Surface preparation is also required for routine maintenance and repair tasks in various industries. It involves cleaning, surface profiling, and removal of contaminants before applying protective coatings or performing repairs.

Water Jetting Machines

Water Jetting Machines for Surface Preparation

Surface preparation generally refers to the stripping of coatings & corrosion using Ultra High Pressure (UHP) water jetting/Hydroblasting equipment at 2000-3000bar (30,000-43,500psi). At these pressures the velocity of the water jet is 500- 600m/sec (Mach 1/speed of sound is 340 m/sec) which will strip the toughest of coatings with plain, fresh water.

Benefits

Benefits of Water Jetting

- Dust free allowing other trades to work in the vicinity

- Minimal waste disposal, 98% less than grit blasting

- Environmentally friendly No contamination of sensitive rotating equipment

- In marine environments removes all chlorides from substrate leaving a perfect surface for new paint

- Unlike grit blasting does not profile steel so does not trap chloride contaminants in the substrate

- Minimal water consumption, most of which evaporates

- Reduces time during dry-docking

- Sheeting not required

- Can be used in wet & windy conditions

- The pump is versatile & can be used for other cleaning & cutting applications

Al Khamis products for Surface Preparation

Pumps

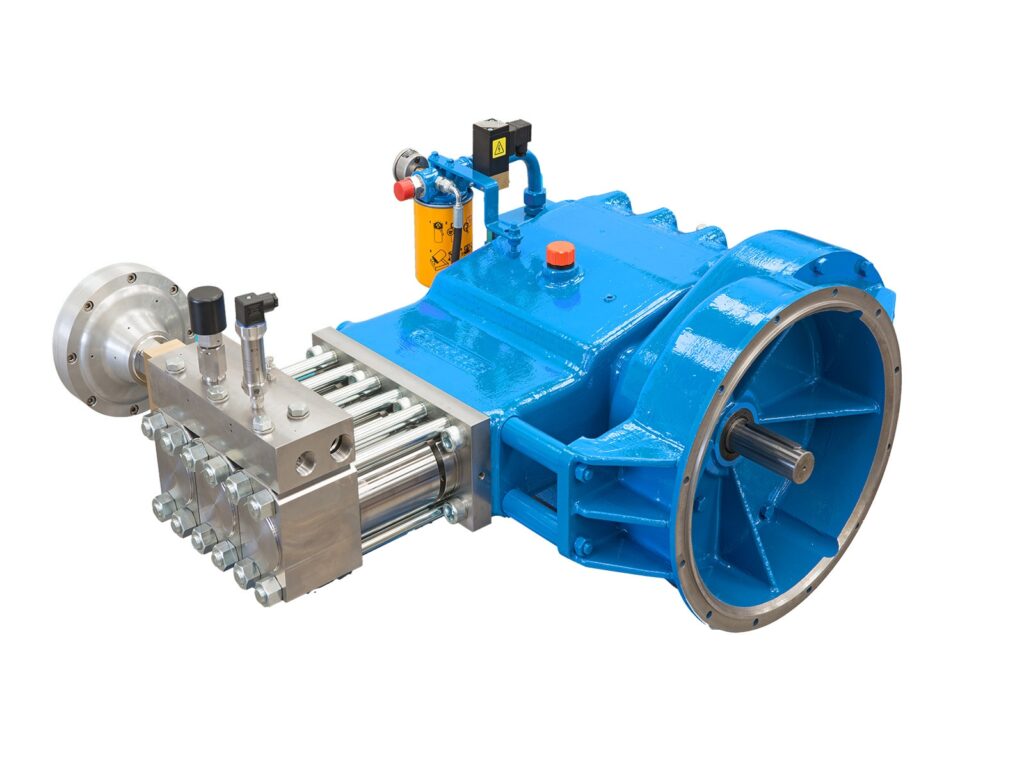

Hughes UB-30

Max Power:

220HP

160kw

Max Pressure:

2800 Bar

at 30 lpm

Max Flowrate:

44 lpm

at 2000 Bar

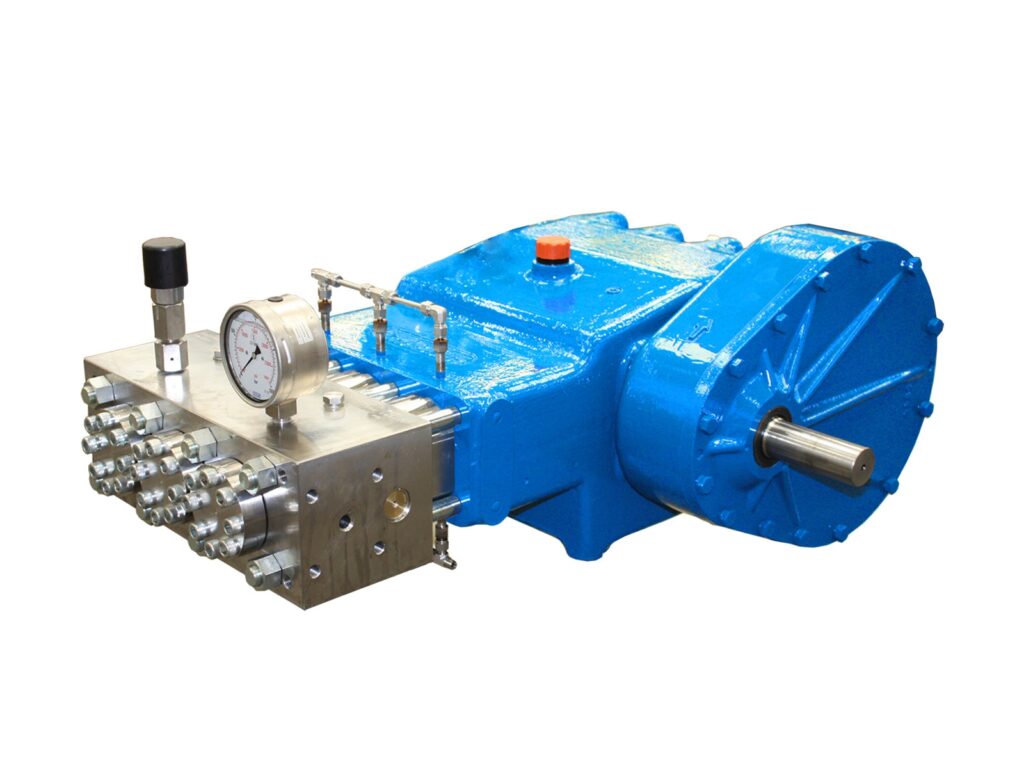

Hughes HP 220

Max Power:

220HP

160kw

Max Pressure:

1400 Bar

at 162 lpm

Max Flowrate:

277 lpm

at 310 Bar

Hughes HP 120

Max Power:

120HP

90kw

Max Pressure:

1400 Bar

at 35 lpm

Max Flowrate:

277 lpm

at 175 Bar

Units

HP 220 Unit

- HP220 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.

HP 550 Unit

- HP550 pump with pressure lubrication & oil cooling.

- Glycerine filled pressure gauge & safety relief valve

- Doosan 6 cylinder with simple auto shutdown control panel

- Stainless steel water tank

- Suitable for single or multi gun / footvalve operation. Applications include surface cleaning / de-scaling, coatings removal, hydro-demolition.

Vertidrive M3

- 60 m2 / 646 ft2 per hour

- 8x faster than manual work

- Horizontal, overhead and vertical surfaces

- Multi-purpose solution

- Interchangeable applications

- 1500 mm cleaning width

- Remote Controlled