✉️ [email protected] | 📞 +971-4-2675252

Home / Applications / UHP Water Blasting

UHP Water Blasting

Al Khamis Equipment LLC sells products designed for UHP water blasting. Read more about our products for abrasive blasting.

UHP Water Blasting

What is UHP Water Blasting?

UHP (Ultra-High-Pressure) water blasting or waterjet blasting is an industrial cleaning method, which uses the force of pressurized water, generated by the blaster’s power source, to achieve the required cleaning effect upon a selected surface. Surfaces which can be cleaned by the blaster can include concrete, metal, wood or stone. Traditional handheld water blasting methods are efficient cleaners but they do present an array of problems and concerns within industrial environments. Let’s explore these issues in the following text

Applications

What is UHP water Blasting used for?

Waterjet blasting can be used to clean industrial surfaces for various reasons. The subjective industries listed below utilize waterjet blasting most often for the following purposes:

- Maritime: as a maintenance and surface preparation technique, water blasting is often used for the removal of any antifouling, paint, rust or marine growth found upon a ship’s hull, deck, storage tanks, oil platforms, cargo hold and more.

- Metal Works: used for eliminating stick weld slag, metal burring, mill scale as well as rust from aged material.

- Aviation: for the removal of aeronautical hydraulic fluids alongside rubber and grease from airstrips.

- Preparation Works: for cleaning away paint, rust, grease, antifouling, salts, grime and more as a step for maintenance or surface preparation.

- Alcohol Processing: for the cleaning of boiler tubes, vessels, tubelines, vats, pipelines and heat exchangers.

- General Cleaning Works: maintaining public/private spaces, buildings and other structures.

- Power stations: for decontamination of fuel capsules, skips, tubes and equipment and for removal of debris.

UHP Water Blasting

How does UHP water blasting work?

Water blasters will vary however in general, the operations of a manually operated water jet blaster are conducted as follows:

The water jet blaster is connected to a water source and cleaning detergent source via separate hose lines.

The power source, which is generally an electric or diesel engine, is switched on.

As water travels along the hoseline, it is filtered of any foreign matter before it is introduced into the blaster’s body, where it is heated and pressurized.

The blaster is ready for UHP cleaning purposes. The operator will pull a trigger to release the pressurized water, through a high pressure exit nozzle, and direct it upon the desired surface.

UHP water blasting has progressed significantly in recent years with the development of robotic technology such as the VertiDrive Magnetic Robotic Crawlers.

Vertidrive

Vertidrive UHP water blasting solutions

The VertiDrive team are the proud designers/suppliers of the hydroblasting (waterblasting) robot solutions such as the VertiDrive M2, VertiDrive M3, VertiDrive M4 and the Vertidrive M7.

All of the previously mentioned VertiDrive solutions are designed to function as remote controlled hydroblasting robots with maximum productivity and minimal operational costs kept in mind. Each functions as a carrying platform for traditional hand-held blasting equipment, an operator simply needs to connect the robot to the hose line of a hand-held water blaster and they are ready to work. The selected solution will then convert the single hose-line of this hand-held system into 3 separate blasting nozzles which spread the water abrasive, with triple efficiency, across the desired surface. The surface profile will remain unchanged post cleaning. Important to note is that the operator will always be located safely on the ground, far away from any hydroblasting related hazards.

Benefits

Benefits of Using Vertidrive

- Multi-purpose

- No need for scaffolding or cherry pickers

- Turns the work into a one-man job

- Safe, clean and efficient operations

- Closed systems available

- Low maintenance robots

- User friendly

Vertidrive Solutions

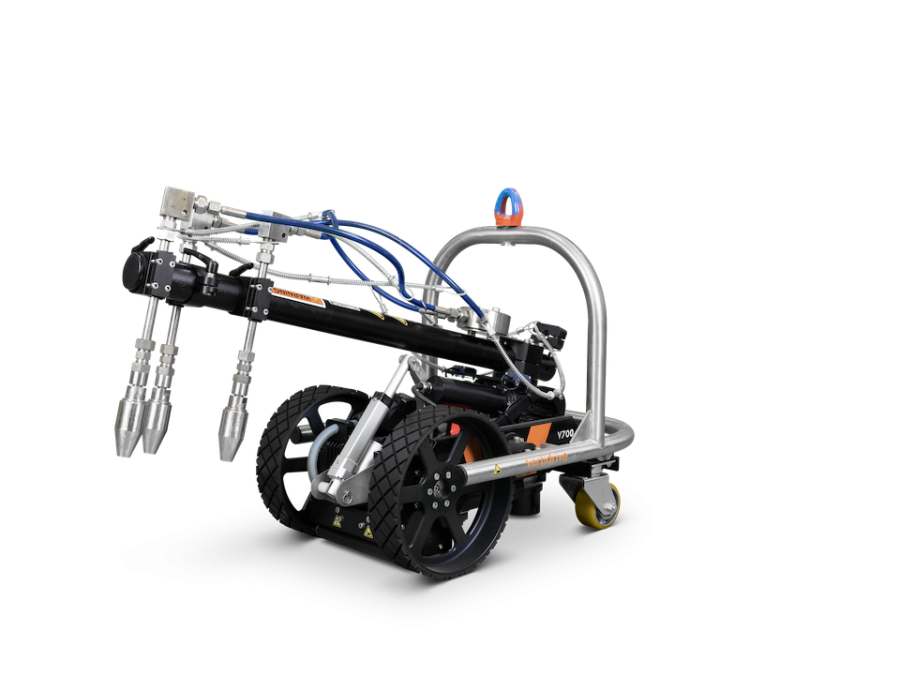

Vertidrive V700

Our new robotic platform is designed specifically for tough industrial environments, ready for future demands. With powerful magnets, the V700 Series can work on any steel surface with magnetic properties, even upside down. Plus, it’s incredibly versatile.

Vertidrive V400

Our V400 Series introduces a break-through solution that surpasses the limitations of traditional UHP blasting methods. No longer accept slow production rates that average 5-8m² (53.8-86.1ft²) per hour, when you can experience an impressive average coverage of 45m² (484.4ft²) per hour.

Vertidrive M7

The VertiDrive M7 is a comprehensive solution for fast and efficient removal of industrial coatings, corrosion, and other types of contamination on large steel surfaces, such as storage tanks, ship hulls, and other large steel structures.